Unveiling a Comprehensive Choice of Durable Undercarriage Parts for Heavy Machinery

Unveiling a Comprehensive Choice of Durable Undercarriage Parts for Heavy Machinery

Blog Article

Discover Undercarriage Components for Heavy Machinery

Understanding the details of undercarriage components is important for the optimal efficiency and longevity of hefty machinery. From track footwear to gears, idlers, and rollers, each element plays an important function in the performance of the equipment. Exploring the specifics of these parts reveals a globe of precision engineering and durability that maintains heavy machinery operating at its top. Stay tuned as we uncover the value of undercarriage parts and discover the maintenance methods that can improve the performance of these important components.

Significance of Undercarriage Components

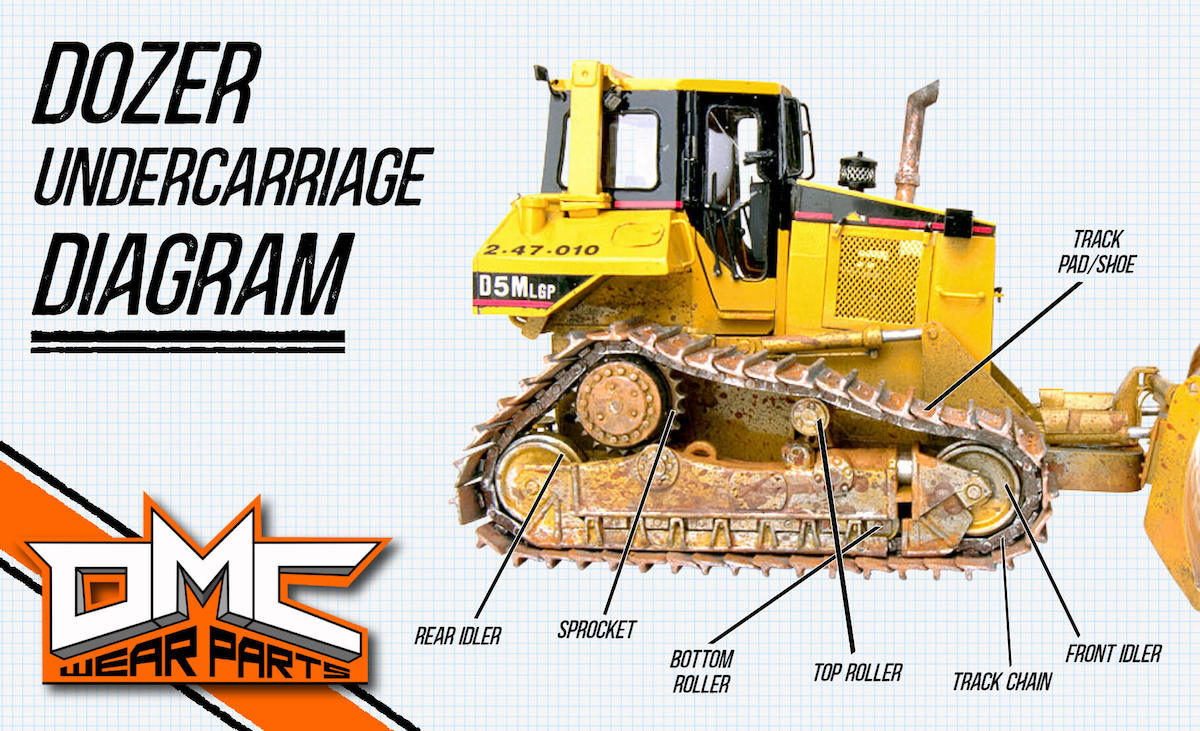

The undercarriage components of heavy machinery play a vital function in ensuring the overall efficiency and durability of the tools. These components, consisting of tracks, rollers, sprockets, idlers, and chains, create the structure whereupon the machine runs. A well-maintained undercarriage not just offers stability and support to the hefty equipment yet additionally contributes substantially to its functional efficiency and performance.

One of the key benefits of purchasing top quality undercarriage parts is the reduction of downtime and upkeep expenses. By utilizing long lasting components that can stand up to the roughness of heavy-duty applications, drivers can decrease the requirement for regular repair services and substitutes, therefore maximizing the machine's uptime and overall life-span.

Furthermore, properly functioning undercarriage parts guarantee optimal weight distribution, traction, and maneuverability, allowing the heavy equipment to run efficiently even in difficult terrains. This integrity is important for sectors such as building and construction, farming, and mining, where equipment performance straight influences project timelines and productivity. In verdict, the value of undercarriage components can not be overemphasized in preserving the effectiveness and long life of hefty equipment.

Kinds of Track Shoes

When thinking about the different sorts of track footwear for hefty equipment, it is important to examine their design and performance in relationship to specific operational demands. Track shoes are important components of the undercarriage system, providing weight, security, and grip distribution for hefty machinery such as excavators, bulldozers, and spider cranes.

The most usual types of track shoes consist of:

** Grouser Shoes **: Featuring raised metal bars (grousers) along the footwear's surface area, these track shoes offer improved grip in challenging terrains like mud, snow, and loosened crushed rock. undercarriage parts.

** Dual Grouser Shoes **: Comparable to grouser footwear however with an added set of grousers, these track footwear use also higher traction and stability, making them optimal for very harsh terrains.

** Triple Grouser Shoes **: With three sets of grousers, these track shoes provide optimal traction and stability, making them ideal for the most requiring problems.

Selecting the best sort of track shoe is necessary for maximizing the performance and longevity of hefty equipment while making sure safety and performance during operations.

Feature of Rollers and Idlers

Rollers and idlers play important duties in supporting and leading the track footwear of hefty machinery during procedure. By avoiding too much slack or tightness in the tracks, idlers contribute to the total stability and efficiency of the machinery.

Furthermore, rollers and idlers interact to maintain the track shoes in placement, avoiding them from slipping or derailing off throughout procedure. Appropriately functioning idlers and rollers are critical for making certain the durability of the undercarriage system and making the most of the machine's performance. you could check here Routine maintenance and examination of these components are important to identify any kind of signs of wear or damage beforehand, preventing expensive fixings and downtime in the long run.

Role of Sprockets in Machinery

Maintenance Tips for Undercarriage Parts

Efficient maintenance of undercarriage elements is crucial for guaranteeing the longevity and ideal efficiency of heavy machinery. Routine inspection of undercarriage parts such as track chains, rollers, idlers, gears, and track shoes is critical to prevent unexpected break downs and expensive repair work. It is likewise important to make certain proper track stress to avoid early wear on elements.

Conclusion

Finally, the undercarriage parts of heavy equipment play a crucial duty in ensuring the smooth performance and long life of the tools. Comprehending the value of track shoes, idlers, rollers, and sprockets, along with applying proper maintenance methods, can substantially influence the general efficiency and efficiency of the equipment (undercarriage parts). Regular examination and prompt replacement of worn-out parts are crucial in making best use of the life-span and productivity of hefty equipment

Rollers and idlers play indispensable roles in supporting and guiding the track shoes of hefty equipment during operation.In heavy machinery, gears serve an essential feature in transferring power from the engine to the tracks, enabling the devices to relocate efficiently and successfully. These components are linked to the axles or last drives of the machinery and work in combination with the tracks to drive the equipment ahead or in reverse. Regular inspection of undercarriage components such as track chains, rollers, idlers, gears, and track blog here footwear is critical to stop pricey repairs and unexpected breakdowns. Understanding the value of track footwear, sprockets, rollers, and idlers, as well as executing proper maintenance methods, can considerably affect the general performance and efficiency of the machinery.

Report this page